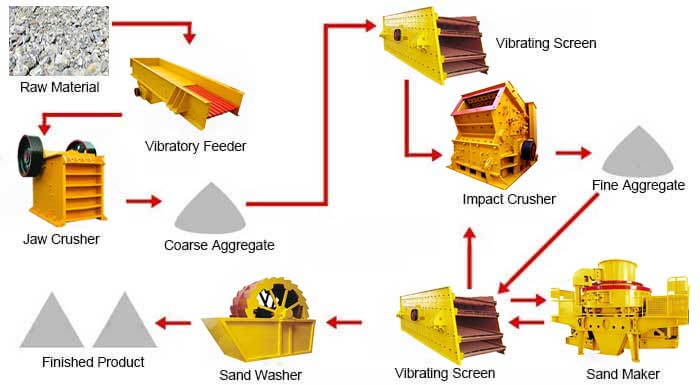

The aggregate making plant has high automation degree, low operation cost, high crushing rate, large output, less pollution, simple maintenance. The mechanism sand produced conforms to the national building sand standard, the product particle size is uniform, the grain shape is good, the gradation is reasonable.

In this aggregate making plant, the processing material is limestone. Limestone is a kind of material which is easy to be broken for making sand, and its silicon content is small. Therefore, the common equipment used in limestone sand production line include:feeding machine, jaw crusher, impact crusher, vibrating screen, sand making machine and sand washing machine etc.

200T/H Aggregate Making Plant Configuration(part):

| NO. | Machines | Model | Power(kw) | Quantity |

| 1 | Vibrating Fedder | ZSW200*120 | 4.4 | 1 |

| 2 | Jaw Crusher | PE750*1060 | 90 | 1 |

| 3 | Imapct Crusher | PF1315 | 200 | 1 |

| 4 | Sand Maker | VSI9526 | 250 | 1 |

| 5 | Vibrating Screen | 3YA1860 | 22 | 2 |

| 6 | Sand Washer | XSD4260 | 15 | 1 |

Vibrating Feeder

First, the stone is uniformly fed into the coarse crusher for the primary crushing. In the production process of vibrating feeder, the bulk and granular materials are uniformly and regularly fed to the receiving device from the storage bin. In the sand and gravel production line, the crushing machinery can be fed continuously and uniformly, and the materials are coarse-sifted.

Jaw Crusher

The large stone is delivered evenly through the bin by the vibrating feeder to the jaw crusher for coarse crushing between the two jaw plates. In the sand production line, because large stones need to be broken into small pieces to carry out the next crushing process, the jaw crusher is often used for primary crushing because of its large handling capacity and uniform particle size.

Impact Crusher

Then the produced coarse material is transported by the belt conveyor to the counterattack crusher for further crushing. The impact crusher has the advantages of uniform grain size, good grain size, adjustable grain size, diversified crushing specifications and so on, which can crush sand and gravel more finely.

Vibrating Screen

The finely broken stone is sent to the vibrating screen by the belt conveyor for screening, and several different specifications of stones are screened out. The stones that meet the granularity requirements are sent to the sand making machine by the finished product belt conveyor for sand making, and those that do not meet the requirements are sent back to the counter type crusher by the belt conveyor for crushing again.

One part of the gravel in the sand machine is made into sand, which is cleaned by the sand washing machine and made into finished sand. The other part is broken again by the sand washing machine.

Sand Making Machine

The pebbles that meet the grain size requirements are sent to the sand-making machine by the finished belt conveyor, and rocks, mine tailings or industrial slag particles with particle size less than 4.75mm are prepared through the sand-making mechanism.After the sand making machine treatment, the stone is sent to the vibrating screen, sieving and output to the finished product warehouse.

Sand Washing Machine

Due to the fierce collision and the stone itself has a certain amount of soil, so artificial sand contains a certain amount of stone powder and mud powder, the presence of mud powder without cleaning treatment will seriously affect the quality of sand.

Sand washing machine is usually selected according to customers’ requirements on the quality of finished products. If the particle size range is 0-5mm, a sand washing machine must be configured to clean the dust outside, so as to make reasonable use of it.

For some customers, maximun water recycling and sludge mannagement are needed to reduce the investment cost and tailings footprint space. LZZG provide one-stop mineral washing plant of different scales to meet your demands.

Related Products

Send us a message

We will provide you with the most professional services.