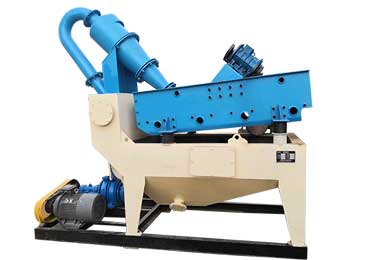

Sand Recycling Machine

Sand recycling machine has been specifically designed to recovery fines mixed in muddy water that discharged from sand washer machines, as well as sculting, desliming dewatering. The highly efficient fines recovery is efficiently improve the economic benefit, reduce disposal cost of tailings and the pollution and damage.

Fines recovery machines are suitable for widely used in sand and gravel washing plant, glass raw material processing system, artificial sand production line, coal mining plant, coarse coal slurry recovery, environmental protection engineering and mud purification.

Or Call Us Now +86-18736301510

1. Effectively recycle >95% fine sand.

2. 12%-15% water content of dewatered sand.

3. Polyurethane screens with blocking, and longs service life than other screen panels.

4. Hydrocyclone separator is lined with polyurethane, which improves the service life of the whole device and can smoothly complete the work of slurry concentration and liquid clarification.

5. Fully recovered fine particles reduce the workload and cleaning cost of sedimentation tank.

6. Recovered fine materials can be directly operated, and supplies to the market, which reduces the stacking time.

7. Specific solution can be designed according to different requirements of users.

Features & Benefits

1. Effectively recycle >95% fine sand.

2. 12%-15% water content of dewatered sand.

3. Polyurethane screens with blocking, and longs service life than other screen panels.

4. Hydrocyclone separator is lined with polyurethane, which improves the service life of the whole device and can smoothly complete the work of slurry concentration and liquid clarification.

5. Fully recovered fine particles reduce the workload and cleaning cost of sedimentation tank.

6. Recovered fine materials can be directly operated, and supplies to the market, which reduces the stacking time.

7. Specific solution can be designed according to different requirements of users.

Working principle

Through rubber pipes sand and water mixture is extracted from cleaning tank into slurry pump. The fine sand is collected by the centrifugal force of cyclone, then fed to the polyurethane screen from the apex spray.

The 0.16-3mm fine sand and water are efficiently separated through the vibration screen. The waste water will flow back to the return box, through weld chute or pipes flowing to a settling pond.

Specifications

| Model | Feeding Size (mm) | Capacity (t/h) | Screen Panel (mm) | Hydrocyclone (mm) | Power (kw) | Overall Size (mm) |

| LZ250 | ≤10 | 20-50 | 900X1800 | 250 | 12.5 | 3100X1300X2700 |

| LZ300 | ≤10 | 40-80 | 900X1800 | 300 | 16.5 | 3100X1300X2700 |

| LZ350 | ≤10 | 60-100 | 900X1800 | 350 | 20 | 3100X1300X2700 |

| LZ550 | ≤10 | 40-100 | 1200X2400 | 250X2 | 26.4 | 3600X1600X2800 |

| LZ650 | ≤10 | 80-160 | 1200X2400 | 300X2 | 34.4 | 3600X1600X2800 |

| LZ750 | ≤10 | 120-200 | 1200X2400 | 350X2 | 41.4 | 3600X1600X2800 |

| LZ900 | ≤10 | 120-250 | 1500X3000 | 300X3 | 51 | 4600X1900X2600 |

| LZ1050 | ≤10 | 150-300 | 1500X3000 | 350X3 | 61.5 | 4600X1900X2600 |

Contact Form

Get in touch with us and one of our team will be with you shortly.

Disclaimer:

All informations contained in this site is provided on an "as is" basis with no guarantees of usefulness or timeliness. For exact specifications, please contact with us: export@lylzzg.com