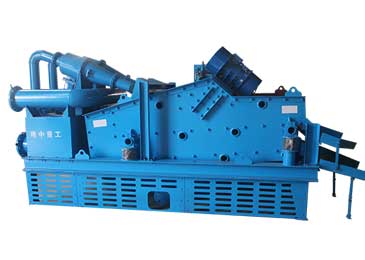

Mobile Slurry Treatment System

LZYN-1020 mobile slurry treatment station is designed for the Building piling slurry, dredging of rivers and lakes, urban sewer dredging and the other industries, which was designed and applied to multi-site operations according to actual requirements.

This mobile slurry treatment station has the characteristics of high production efficiency, excellent working effect, convenient and flexible operation and can meet the requirements of various working environment.

Or Call Us Now +86-18736301510

1. After separation by the slurry treatment system, the sludge contained in mud water is <3%, which can meet the mud use requirements for clearing, pouring and retaining walls, while the sand moisture content is <15%, which can be directly sold.

2. High efficiency, large processing capacity, low-cost operation.

3. The cyclone can adjust for different materials and concentration to achieve ideal separation effect.

4. Good sealing, prevent leakage and mud splash, the working site is clean and tidy.

5. The whole machine adopts anti-corrosion treatment, and the inside of the road is brushed with FRP, which greatly increases the service life.

6. Screen panels, electric control boxes and other related accessories, all use well-known brands to ensure safe and reliable operation.

Features & Benefits

1. After separation by the slurry treatment system, the sludge contained in mud water is <3%, which can meet the mud use requirements for clearing, pouring and retaining walls, while the sand moisture content is <15%, which can be directly sold.

2. High efficiency, large processing capacity, low-cost operation.

3. The cyclone can adjust for different materials and concentration to achieve ideal separation effect.

4. Good sealing, prevent leakage and mud splash, the working site is clean and tidy.

5. The whole machine adopts anti-corrosion treatment, and the inside of the road is brushed with FRP, which greatly increases the service life.

6. Screen panels, electric control boxes and other related accessories, all use well-known brands to ensure safe and reliable operation.

Working principle

The slurry to be treated enters the lower layer of the screener through the feed pipe, and the lower screen plate (hole 5mm) sifts out the large particle material of >5mm, and the small particle material and water under the screen panel enter the water tank, then is pumped out through the slurry pump, and feeded into the high pressure hydrocyclone separator, and the separator realizes concentration and separation of the solid particles.

The slurry having a concentration of about 50% flows out from the bottom outlet of the hydrocyclong, enters the upper layer of the screen machine, and the dewatering operation is completed by the upper sieve plate (hole seam 0.16 mm)to realize the slurry drying; the waste water with less than 3% suspended matter flows into the return tank through the overflow port of the separator, and is discharged through the discharge pipe.

Specifications

| Model | Capacity (m³/h) | Power (kw) | Electronic-controling | Screen size (mm) | Weight (kg) | High pressure separator |

| LZYN1020 | 120 | 2.2*2 | Chint electric appliance | 4640X2050X1800 | 3300 | FM250*2 |

Contact Form

Get in touch with us and one of our team will be with you shortly.

Disclaimer:

All informations contained in this site is provided on an "as is" basis with no guarantees of usefulness or timeliness. For exact specifications, please contact with us: export@lylzzg.com