Sand washing and recycling integrated machines and fine sand recycling machines are both commonly used in the cleaning and recycling stage of machine-made sand, but what is the difference between the two?

1. Different structure

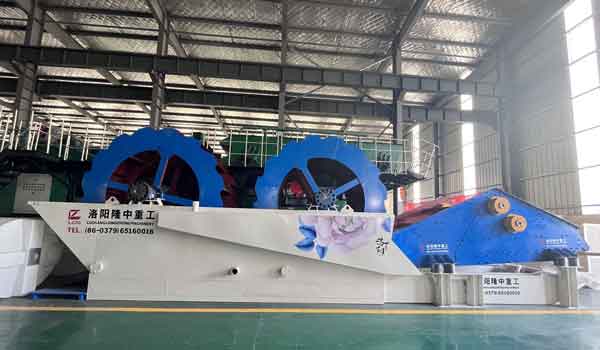

The integrated sand washing and recycling machine is composed of a separator, a dewatering screen, an impeller separator, a reducer, a slag paddle pump, a cleaning box, a sand settling nozzle, and other components. It has the dual functions of a sand washing machine and a recycling machine.

The fine sand recycling machine is mainly composed of a washing tank, mortar pump, motor, cyclone, linear vibrating screen, return box, etc. When used in sand and gravel plants, the main function is to wash sand and separate sediment, so it is also called a fine sand dehydrator, sediment separator, and sediment extraction machine; when used in concentrators, the main function is to recover tailings, so it is also called tailings. My recycling machine.

2. The principle of sand washing and recycling is different

The sand-water mixture of the integrated sand washing and recycling machine enters the cleaning box, is separated by the impeller separator, and then enters the lower dewatering screen for dehydration treatment. The wastewater (containing a large amount of fine sand, mud paddle, dust, and other impurities) flowing out of the cleaning tank is transported to the separator by the slag paddle pump, and then the fine sand after centrifugal classification and concentration is discharged into the upper layer of the dewatering screen through the sand settling nozzle. The waste water, mud, dust, impurities, etc. in the cleaning box are discharged into the high-level return tank through the overflow port of the separator, and then the upper layer produces the coarse sand of the finished material, and the lower layer produces the fine sand of the finished material or a mixture of coarse and fine sand.

When the fine sand recovery system is working, the mortar pump and cement mixture are transported to the cyclone, and the cyclone is centrifugally classified. The concentrated fine sand is supplied to the vibrating dewatering screen through the discharge box and dewatered by the vibrating dewatering screen. A small amount of fine sand is returned to the washing tank from the return box. When the liquid level of the washing tank is too high, it is discharged through the overflow pipe. The fineness modulus can be adjusted by changing the rotational speed of the centrifugal pump, changing the slurry concentration, adjusting the overflow water volume, and replacing the sand nozzle, to complete the three functions of cleaning, dehydration, and classification.

3. Different production line configurations

In the sand production line, the fine sand recovery machine is mainly used after the sand washing machine (used in conjunction with the sand washing machine) to recover a large amount of fine sand lost by the sand washing machine in the traditional sand making industry (more than 20% when the loss is serious), While improving economic benefits, it also reduces the processing cost of tailings and the pollution and damage to the environment caused by the loss of fine sand.

The integrated sand washing and recycling machine does not need to be equipped with a sand washing machine. It has its own sand washing equipment and can be equipped with a double-wheel or single-wheel sand washing machine according to requirements.

In a word, the integrated sand washing and recycling machine are mainly divided into the sand washing part and the fine sand recycling part. There are two parts: impeller type sand washing machine + fine sand recycling machine (general fine sand recycling machine or dewatering fine sand recycling machine, can also According to the sand production requirements, the multi-layer dewatering screen is configured, which is relatively easy to understand. If you have any other questions, please leave a message.

Send us a message

We will provide you with the most professional services.