The advantage of the polyurethane screen used in the fine sand recovery machine is that it can well recover a large amount of fine sand lost by the sand washing machine. LZZG’s fine sand recovery machine, also known as fine sand recovery system, tailings recovery machine, silt separator, etc., is equipment specially developed for dehydration, de-intermediation, desliming, and fine recovery of slurry materials. While this equipment improves economic efficiency, it also reduces the cost of tailings treatment and the pollution and damage caused by the loss of fine sand to the environment. The fine sand recovery machine can be widely used in the sand and gravel processing system of the hydropower station, the glass raw material processing system, the artificial sand production line, the recovery of the coarse slime of the coal preparation plant, the environmental protection project, and the mud purification, etc.

Features of polyurethane screen

1. In the traditional artificial sand wet processing technology, when the artificial sand is washed and dewatered using a spiral sand washer or wheel sand washer, the loss of fine sand in the artificial sand can hardly be controlled. The use of this fine sand recovery system can effectively reduce the loss of fine sand and keep it within 5%-10%, which solves the problem of the high fineness modulus of finished sand in the artificial aggregate processing system. The problem of low stone powder content.

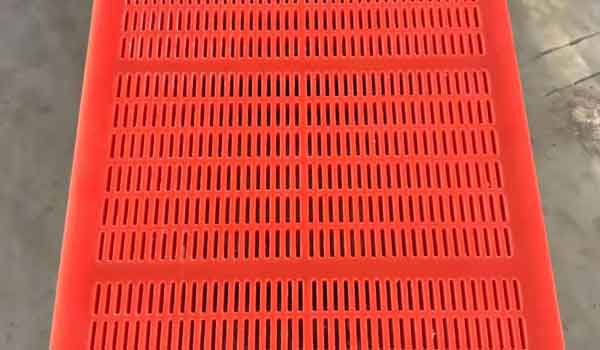

2. The vibrating screen adopts a polyurethane screen which has a longer life than other types of screens and will not block holes.

3. The mud-sand separator is lined with polyurethane, which improves the service life of the entire device and can smoothly complete slurry concentration and liquid clarification.

4. It can recover 95% of the fine particles in the total discharge, and has the technical and economic advantages of other types of crusher equipment.

5. The fine particles are fully recovered, which reduces the workload of the sedimentation tank and reduces the cleaning cost of the sedimentation tank.

6. The storage time of fine materials is reduced, and they can be directly operated and supplied to the market.

7. The same solution can be designed according to the different requirements of users.

Polyurethane screens and screens are widely used in screening machines for metallurgy, mining, coal, building materials, water conservancy, road construction, and other work. They are the replacement products of steel plate punching screens, steel wire meshes, stainless steel screens, and rubber screens. It has the advantages of a lightweight, high screening power, no blocking of holes, resistance to interference, impact resistance, tear resistance, long life (2-3 times that of stainless steel sieve plates), and low noise.

Advantages of LZZG polyurethane screen

1. Its service life is long, and its carrying capacity can be increased. Because the polyurethane elastic screen uses steel wire rope as the skeleton material, and the polyurethane itself has a very high elastic modulus, high-strength impact absorption, and high wear resistance, it has high tensile strength. Its load-bearing capacity is more than 2.5 times that of the rubber screen. Its service life is 8-10 times longer than that of ordinary metal screens, 3 times that of stainless steel screens, and 3.9 times that of natural rubber. It was the world’s wear-resistant screen material at that time. The material produced by the polyurethane screen is a polymer organic elastomer, which has excellent abrasion resistance, flex resistance, and load capacity. The material produced by the polyurethane screen has been specially treated to ensure that it will never delaminate under the action of long-term alternating loads.

2. High screening power. The screen surface has the function of self-cleaning inside, does not block holes, and has high screening power. Due to the strong water permeability of polyurethane and the large sieve cone angle (140°), it can effectively avoid the adhesion of wet fine particles, so it is suitable for the screening and classification of wet fine materials. The polyurethane screen is made of imported materials. Its elastic body and its excellent relaxation function can effectively avoid the appearance of blocking holes under dynamic conditions.

3. High screening accuracy. The production technology of the polyurethane screen is made of mold casting technology, the aperture is accurate, the screening quality is high, and the particle size of the material under the screen can perfectly meet the needs of users.

4. Wide range of applications and stronger professional applicability. It is suitable for any type of vibrating screen machine and fine sand recovery machine and can be produced by measuring machine. Polyurethane screens are professionally used in hydropower stations, building materials, and other metal beneficiation mining. For the screening of various materials within the range of 0.1mm-170mm, both dry and wet sieving will not affect the sieving power. The superiority of the polyurethane screen surface is more fully demonstrated for the dehydration and de-intermediation sieve in the range of 0.5m-3mm. Polyurethane has a low density (1.32kg/m3) and is lighter than a metal screen surface, which can reduce the unit consumption of production.

If you need to customize the fine sand recycling machine, you can leave a message on the official website for consultation, or you can directly call our 24-hour hotline.

Send us a message

We will provide you with the most professional services.