In the fine sand recovery operation, the sand pump is an important part of the fine sand recovery equipment. As the working hours of the equipment increase and the processing capacity increases, various problems will occur in the sand pump. As one of the necessary parts of the fine sand extraction equipment, the sand pump often suffers a series of failures due to the influence of the working environment. How to deal with the failure of the sand pump? This article will give you a detailed analysis of the reasons and solutions for the failure of the sand pump.

1. The main reason for the excessive power of the sand pump shaft is that the packing cover is too tight, the friction bearing in the pump is damaged, and the motor shaft and the pump shaft are not aligned or parallel. The filler heats up, causing friction in the pump and causing bearing damage. Or under the condition that the driving device belt is too tight, the pump flow is too large, the speed is too high, and the motor shaft and the pump shaft are not parallel to each other, it is easy to cause excessive power of the sand suction pump shaft.

Solution: When this kind of problem occurs, you need to loosen the material cover, eliminate friction or replace the bearing, and adjust the belt to adjust the pump speed, properly grasp the speed, adjust the motor shaft and the sand suction pump shaft. It can be solved.

2. The main reason why the sand pump cannot be filled is water leakage in the suction pipe or filling, special error, or damage to the impeller.

Solution: When this problem occurs, you need to plug the leaking straw and replace it with a new impeller to eliminate the blockage.

3. Short life of sand pump bearings and serious wear are the main reasons for the misalignment or imbalance of the motor shaft and pump shaft, or insufficient lubrication, which will cause serious wear of the sand pump shaft and reduce the service life.

Solution: At this time, we should reassemble the sand pump shaft or add lubricating grease.

4. The main reason for the overheating of the sand pump bearing is that there is too little lubricating grease, which leads to insufficient lubrication, which causes the friction of the bearing to increase, and the bearing is damaged in severe cases.

Solution: We need to regularly replace the sand pump lubricant to prevent insufficient lubrication. If the sand pump shaft is severely worn, it needs to be replaced in time.

5. In the fine sand recovery process, when the suction pipe of the sand suction pump or the filling part leaks and turns incorrectly, it is easy to happen that the sand suction pump cannot suck water. At the same time, this phenomenon is prone to occur when the impeller is damaged and the suction pipe is blocked.

Solution: In the actual production process, once a similar problem occurs, we should block the leaking part in time, check the steering, and replace it with a new impeller.

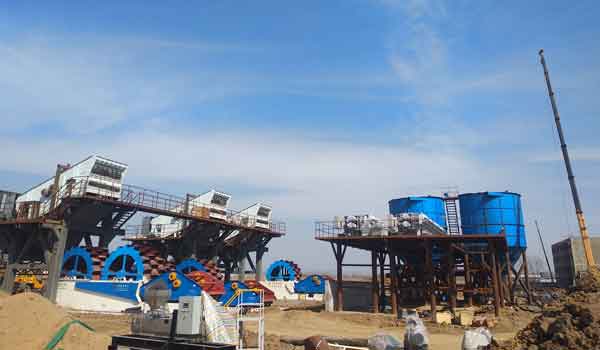

The above are the common faults and solutions of the sand pump of the fine sand extraction equipment. I hope that it can be helpful to everyone when using the fine sand extraction equipment. LZZG is a professional fine sand recycling equipment manufacturer integrating R&D, production, and sales. If you need to buy a fine sand recovery machine, welcome to visit our factory.

Send us a message

We will provide you with the most professional services.