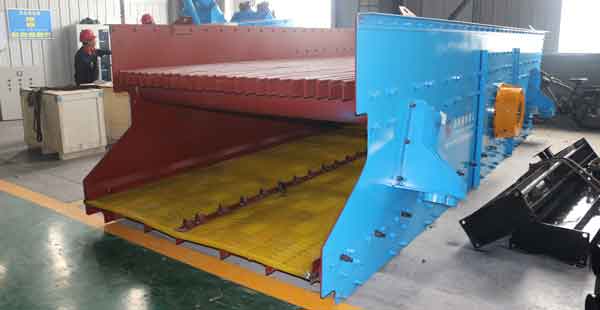

The linear vibrating screen uses the vibration motor as the source of vibration so that the material is thrown up on the screen while moving forward in a straight line. The material enters the feed inlet of the screening machine evenly from the feeder and produces several kinds through the multi-layer screen. The oversize and undersized items of specifications are discharged from their respective outlets. It has low energy consumption, high output, simple structure, easy maintenance, fully enclosed structure, no dust spillage, automatic discharge, and is more suitable for assembly line operations.

How to fix the vibrating sand screen panel?

1. Bolt compression and fixation

The connection method of pressing the screen surface on the screen frame with bolts is called bolt compression. This fixing method is mostly suitable for fixing the middle part of the sieve plate with a thickness greater than 8mm, rubber sieve surface, bar sieve surface, and textile screen with a large diameter of the screen.

2. Inclined plate compression

The method of fixing the two sides of the screen surface on the screen frame through the inclined plates and bolts on the upper frame is called inclined plate compression. This fixing method is often used for thin steel plate punching screens for medium-grade screening, and rubber and polyurethane screens.

3. Pull hook tension

Turn the screen or the end of the screen into a hook shape, or wrap the edge of the screen into a hook shape with a thin steel plate and a rubber pad, and then fix it with a hook and bolt. It is called hook tension. The former is suitable for screen plates or woven screens with a thickness of less than 6mm, and the latter is suitable for screens with smaller screen diameters.

4. Wooden wedge compression

The method of fixing the screen surface on the vibrating screen frame with wooden wedges is called wooden wedges compression. This compaction method is suitable for slotted screens and punched screens.

How to install the vibrating sand screen reducing valve?

1. Before assembling the linear screen pressure reducing valve, the iron filings, and other debris in the pipeline should be blown off, and the mineral oil on the pressure reducing valve should be washed away. The gas source should be purified.

2. The linear screen pressure reducing valve can be installed at any position, but it is best to install it in the vertical direction of the linear vibrating screen, that is, the handle is on the top for easy operation. Generally, only one pressure gauge is installed for each pressure reducing valve, and the installation direction of the pressure gauge is convenient for observation.

3. Pay attention to the direction of airflow when installing the linear screen pressure reducing valve, and install it in the direction of the arrow shown on the pressure reducing valve or the setting device. Be careful not to connect the input and output ports in reverse.

4. When the pressure reducing valve is assembled, the surface of the sliding part should be coated with a thin layer of lubricant. It is necessary to ensure that the valve stem is concentric with the diaphragm, so as not to jam the valve stem during work and affect the working performance.

5. To ensure the service life of the pressure reducing valve, when the linear screen pressure reducing valve is not in use, the handle should be loosened to return to zero to avoid deformation and premature deterioration of the diaphragm due to long-term pressure, which will reduce the pressure regulation accuracy.

Send us a message

We will provide you with the most professional services.