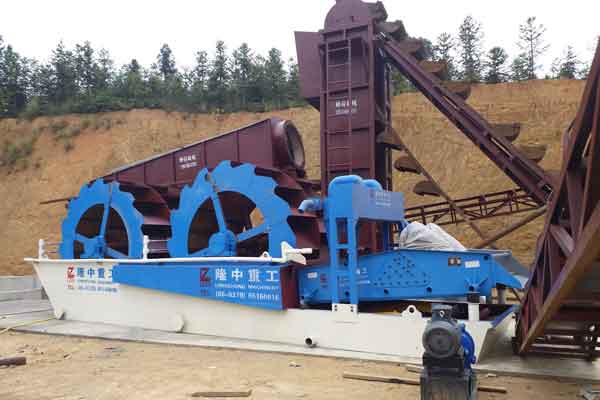

Sand washing machines are widely used. Many people don’t know about bucket wheel sand washing machines. Today, I will take you to learn more about bucket wheel sand washing machines. It is very important to debug the large-scale four-slot wheel bucket sand washer, so we need to understand the basic operating requirements for the debugging of the sand washer.

Debug before starting

1. It is necessary to check whether there is enough grease at each lubrication point before starting the machine, and the connecting bolts must be tightened.

2. After starting the motor, the sand washer can run normally before adding materials.

3. To stop running, stop feeding first. After the material in the sand washer is unloaded, it can be shut down.

4.After the sand washer has been running for a period of time, it is necessary to check the wear of the internal parts of the sand washer.

Precautions for installation and debugging

1. The installation of sand washing machine equipment needs to be installed on a solid concrete foundation, and it needs to be fixed with anchor bolts.

2. During the installation process, pay attention to the vertical main body of the machine.

3. The power cord and control switch needs to be configured with the power supply of the device.

5.After the inspection of each part of the equipment, a no-load experiment is required. If the experiment runs normally, we can proceed to formal production.

Precautions before troubleshooting

1. The wear of the large four-groove bucket sand washer bearing refers to the damage of the sealing ring, and the wearing parts are not easy to clean. The sealing ring should be refueled or replaced as needed, and the sand washer equipment needs to be cleaned regularly.

2. The gears of the large four-slot wheel bucket sand washer are easy to damage, and should be refueled according to regulations. Secondly, the low-speed shaft of the large-scale four-trough bucket sand washer and the reducer must achieve the required parallelism.

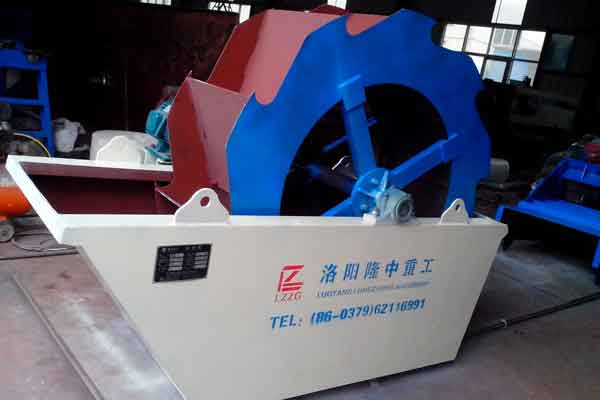

Features of Wheel Sand Washing Machine

1. The structure of the bucket wheel sand washing machine is relatively simple, and the structure is designed, the impeller drive bearing device of the equipment is isolated from the water and water-receiving materials, which reduces the damage of the equipment and increases the production efficiency of the sand washing machine.

2. The loss of fine sand and stone powder is very small, and the sand washing gradation and fineness modulus meet the standard requirements. Except for the filter screen, the bucket-type sand washing machine has almost no wearing parts. Long use time, no long-term maintenance.

3. The wheel is a sand washer with the advantages of convenient maintenance, large capacity, low power consumption, and high cleanliness. The novel sealing structure, fully-sealed oil bath transmission device, and adjustable overflow weir plate ensure the high efficiency and durability of this series of products, as well as good cleaning and dehydration effects.

Send us a message

We will provide you with the most professional services.