With the continuous development of urban infrastructure, natural sand can no longer solve the dilemma of using sand. More and more machine-made sand is processed to replace natural sand. Among them, the machine-made sand produced by the cobblestone machine-made sand production line is a high-quality sand and gravel product with good grains, reasonable gradation, and particle size that meets the needs of the project. With this advantage, cobblestone machine-made sand production lines are widely used. Let’s take a look at the manufacturer’s price of a 500T cobblestone machine-made sand production line with LZZG.

1. Cobblestone materials

Cobblestone is compressive, wear-resistant, and corrosion-resistant, making it an ideal natural green building stone. Cobblestones are widely distributed and have the advantages of rich resources, good building characteristics, and easy development and utilization. Natural pebbles are often processed on the pebbles production line and used as construction sand and artificial sand processing raw materials. They are widely used in the field of real estate construction, highway and railway construction, etc.

2. Cobblestone machine-made sand production line

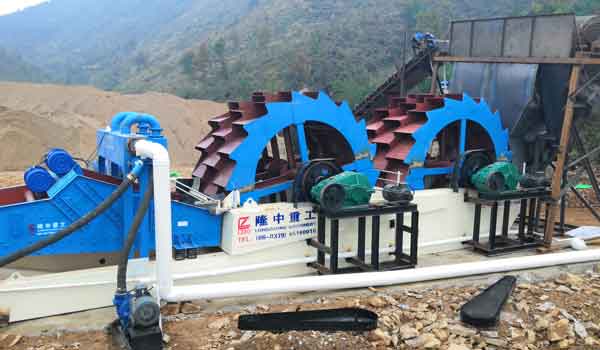

Cobblestone machine-made sand production line is a series of production lines for crushing pebbles and making sand. It consists of a crushing production line for crushing cobblestones and a cobblestone sand production line for making sand from cobblestones. Under normal circumstances, the two lines are organically combined, that is, the cobblestone crushing production line is combined with sand-making machines, sand washing machines, and other sand-making equipment to form a cobblestone machine-made sand production line. 500T refers to the processing capacity of the production line. The crushing sand-making equipment is reasonably configured according to the processing capacity.

500T cobblestone machine-made sand production line configuration

Vibrating feeder→jaw crusher→cone crusher (reaction crusher added as needed)→circular vibrating screen→sand making machine→circular vibrating screen→sand washing machine

The principle analysis of the production line

The jaw crusher and cone crusher in the cobblestone machine-made sand production line are responsible for the primary and secondary crushing, while the counter-attack or sand-making machine performs integral crushing. The entire production process can greatly reduce the negative material formed after screening and reduce the loss of the entire cobblestone machine-made sand production line.

3. Cobblestone machine-made sand production line manufacturers

There are many manufacturers of cobblestone machine-made sand production lines. It is convenient to choose the manufacturer. It is recommended that you must find out the details of the manufacturer. If possible, you must go to the manufacturer’s production plant to see how strong it is. Seeing is believing. LZZG, as a professional cobblestone machine-made sand production line manufacturer, can design the process of cobblestone machine-made sand for customers. According to the actual needs of customers, different equipment can be configured, and a complete set of the production line design, manufacturing, maintenance, and installation can be contracted. Whether 200t or 500t per hour cobblestone machine-made sand production line, the cobblestone products produced meet the standards of high-level construction.

4. Price of cobblestone machine-made sand production line

In addition to paying attention to the performance and quality of the cobblestone machine-made sand production line itself, the price of the production line is undoubtedly the user’s concern. The price of the 500T cobblestone machine-made sand production line is determined by many factors. If you want to buy a cobblestone machine-made sand production line that suits you at a reasonable price, then LZZG has a reasonable price, and in terms of quality, all products have passed quality certification. It is cost-effective to buy. According to the actual needs of users, suitable production line configuration can be configured for users according to their needs, so that each device can play a better role.

Send us a message

We will provide you with the most professional services.