Screening is an indispensable link in the sand and gravel aggregate production line. The purpose of screening is mainly to separate materials with different properties. When the crushing equipment crushes raw materials such as sand and ore, it needs to be screened to ensure that the sand and gravel materials meet the crushing requirements of the crushing equipment.

Screening machinery is divided into circular vibrating screens, linear vibrating screens, resonance screens, fixed screens, roller screens, equal thickness screens, cylindrical screens, etc. According to their structure and movement characteristics, different screens have their characteristics. The more commonly used types of mine production are circular vibrating screens and linear vibrating screens in the sand and gravel aggregate production line. This article introduces the 7 differences between linear vibrating screens and circular vibrating screens.

Introduction of Circular Vibrating Screen and Linear Screen

Circular vibrating screen

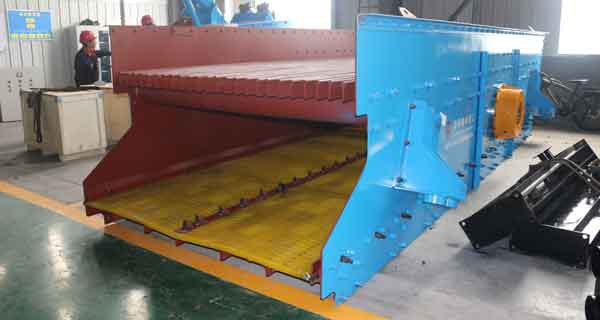

The circular vibrating screen uses the centrifugal force generated by the rotation of the eccentric block in the vibrator to make the screen box and the vibrator perform continuous circular or approximate circular motion. The materials follow the sieve box to make continuous throwing motion on the inclined screen surface, layering when throwing, and particles passing through the sieve when falling.

The circular vibrating screen has the characteristics of reliable structure, high screening efficiency, strong excitation force, sturdiness and durability, convenient maintenance, and safe use. It is widely used in mining, building materials, transportation, energy, chemical, and other industries.

Linear vibrating screen

The linear vibrating screen is widely used in the mining industry. It uses the vibrating motor to excite the vibrating force to cause the material to be thrown up on the screen and move forward in a straight line. The material enters the inlet of the screen evenly from the feeder and passes through multiple layers. The screen produces several specifications of over sieve and underserved, which are discharged from their respective outlets.

The linear vibrating screen has a compact structure, reasonable vibration parameters, stable movement, low energy consumption, high output, high screening and dehydration efficiency, fully enclosed structure, no dust spillage, and automatic discharge characteristics, which is more suitable for assembly line operations.

7 main differences between circular vibrating screen and linear screen

1. Different trajectories

The material on the linear screen moves forward in a straight line, and the material on the circular vibrating screen moves in a circular motion.

2. Different exciters

The linear vibrating screen vibrator is composed of two shafts and works by the principle of vibration motor excitation, so it is also called a double-shaft vibrating screen.

The circular vibrating screen is also called a single-shaft vibrating screen because the exciter is a shaft and uses an inertial motor to work.

3. Different plugging phenomenon

The material of the linear vibrating screen moves smoothly on the screen surface. If the material is not uniformly fed or the material has high humidity and viscosity, it is easy to block the holes.

The material of the circular vibrating screen moves in a parabolic circular trajectory on the screen surface so that the material is dispersed as much as possible to improve the bounce force of the material, and the material stuck in the screen hole can also jump out, reducing the hole blocking phenomenon.

4. The installation inclination is different

Generally speaking, the inclination angle of the screen surface of the linear vibrating screen in production is small, and the height of the screen is reduced, which is convenient for process layout.

The circular vibrating screen usually has an installation inclination angle of 15-20 degrees, which can change the moving speed of the material along the screen surface and improve the screening efficiency.

5. Different materials

The selection of materials for the production of linear vibrating screen is mainly light-weight plate or stainless steel plate.

The selection of the circular vibrating screen is thicker, and the box is made of manganese steel, which can resist the impact of the material during the screening process.

6. Different appearance and structure

The linear vibrating screen can adopt a fully enclosed structure without dust spillage, which is more conducive to environmental protection.

The vibration exciter of the circular vibrating screen is arranged above the center of gravity of the screen box, which is conducive to the rapid dispersion of materials, and the processing capacity per unit time is higher than that of the linear vibrating screen.

7. Different applicable fields

Linear screens mainly screen fine particles, light specific gravity, and low-hardness materials, mainly dry powder, fine granular or micro-powder materials, and are generally used in food, chemical, building materials, and pharmaceutical industries.

The circular vibrating screen mainly screens materials with high specific gravity, large particles, and high hardness, and is widely used in mining industries such as mines, coal, and quarries. Besides, circular vibrating screens can also be used for some difficult-to-screen materials.

Send us a message

We will provide you with the most professional services.